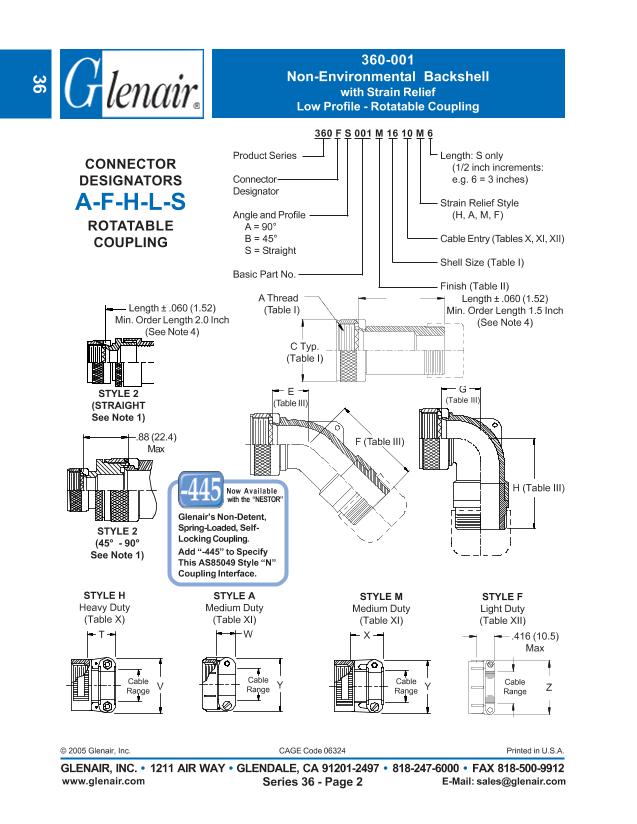

360HS001M2106H3

| Model | 360HS001M2106H3 |

| Description | Connector Accessory, Backshell, Aluminum Alloy, ROHS COMPLIANT |

| PDF file | Total 5 pages (File size: 318K) |

| Chip Manufacturer | GLENAIR |

Glenair Backshell and Accessory Material and Finish Options

Backshell and accessory base materials, plating options, specifications and codes

Code

A

AB

AL

B

C

E

G

J

JF

LF

M

MT

N

NC

NF

P

T

TP2

U

UC

UCR

UF

XAL

XB

XM

XMT

XO

XW

XZN

Z1

Z2

ZC

ZCR

ZL

ZM

ZMT

ZN

ZNU

ZR

ZU

ZW

Material

Aluminum

Marine Bronze

Aluminum

Aluminum

Aluminum

Aluminum

Aluminum

Aluminum

Aluminum

Aluminum

Aluminum

Aluminum

Aluminum

Aluminum

Aluminum

Stainless Steel

Aluminum

Titanium

Aluminum

Aluminum

Aluminum

Aluminum

Composite

Composite

Composite

Composite

Composite

Composite

Composite

Stainless Steel

Aluminum

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Aluminum

Aluminum

Aluminum

Stainless Steel

Stainless Steel

Finish

Cadmium, No Chromate

Unplated

AlumiPlate, Clear Chromate

Cadmium, Olive Drab

Anodize, Black

Chem Film

Anodize, Hardcoat

Cadmium, Gold

Cadmium, Gold

Cadmium, Clear

Electroless Nickel

Nickel-PTFE

Cadmium, Olive Drab

Zinc-Cobalt, Olive Drab

Cadmium, Olive Drab

Electrodeposited Nickel

Cadmium, No Chromate

Electrodeposited Nickel

Cadmium, Black

Zinc-Cobalt, Black

Zinc-Cobalt, Black

Cadmium, Black

AlumiPlate

Unplated Black

Electroless Nickel

Nickel-PTFE

Unplated Light Brown

Cadmium, Olive Drab

Zinc-Nickel, Black

Passivate

Gold

Zinc-Cobalt, Black

Zinc-Cobalt, Black

Electrodeposited Nickel

Electroless Nickel

Nickel-PTFE

Zinc-Nickel, Olive Drab

Zinc-Nickel, Black

Zinc-Nickel, Black

Cadmium, Black

Cadmium, Olive Drab

Finish Specification

SAE-AMS-QQ-P-416 Type I Class 3

MIL-DTL-83488, Class 2, Type II over electroless nickel

SAE-AMS-QQ-P-416 Type II Class 3

AMS-A-8625 Type II Class 2

MIL-DTL-5541 Type 1 Class 3

AMS-A-8625 Type III, Class 1, .001" thick

SAE-AMS-QQ-P-416 Type II, Class 2 over electroless nickel

SAE-AMS-QQ-P-416 Type II, Class 2 over electroless nickel

SAE-AMS-QQ-P-416 Type II Class 2 over electroless nickel

AMS-C-26074 Class 4 Grade B; ASTM-B-733, SC 2, Type IV

GMF-002 Type II Class 1

SAE-AMS-QQ-P-416 Type II Class 3 over electroless nickel

ASTM B 840 Grade 6 Type D over electroless nickel

SAE-AMS-QQ-P-416 Type II Class 2 over electroless nickel

SAE-AMS-QQ-N-290 Class 1 Grade F

SAE-AMS-QQ-P-416 Type I Class 3

SAE-AMS-QQ-N-290 Class 1 Grade F

SAE-AMS-QQ-P-416 Type I Class 3

ASTM B 840 Grade 6 Type D over electroless nickel

ASTM B 840 Grade 6 Type D over electroless nickel

SAE-AMS-QQ-P-416 Type II Class 2 over electroless nickel

MIL-DTL-86448, Class 2, Type II over electroless nickel

AMS-C-26074

GMS-002 Class 2 Type II

SAE-AMS-QQ-P-416 Type II Class 3 over electroless nickel

ASTM B841 Grade 5 over electroless nickel

SAE-AMS-SAE-AMS-QQ-P-35 Type VI

MIL-DTL-45204 Class 1 over electroless nickel

ASTM-B840, Grade 6

ASTM-B840, Grade 6

SAE-AMS-QQ-N-290 Class 1 Grade F

AMS-C-26074 Class 1 Grade A

GMF-002 Type II Class 3

ASTM B841 Grade 5 over electroless nickel

ASTM B841 Grade 5 over electroless nickel

ASTM B841 Grade 5 over electroless nickel

SAE-AMS-QQ-P-416 Type II Class 3

SAE-AMS-QQ-P-416 Type II Class 2 over electroless nickel

Hrs. Salt

Spray

48

1000

1000

96

336

168

336

500

1000

1000

48

1000

500

350

1000

500

48

96

48

350

350

1000

2000

2000

2000

2000

2000

2000

2000

1000

48

Electrical

Conductivity

Conductive

Conductive

Conductive

Conductive

Non-Conductive

Conductive

Non-Conductive

Conductive

Conductive

Conductive

Conductive

Conductive

Conductive

Conductive

Conductive

Conductive

Conductive

Conductive

Conductive

Conductive

Conductive

Conductive

Conductive

Non-Conductive

Conductive

Conductive

Non-Conductive

Conductive

Conductive

Conductive

Conductive

Conductive

Conductive

Conductive

Conductive

Conductive

Conductive

Conductive

Conductive

Conductive

Conductive

Operating Temp.

Range

-65 to +175°C

-65 to +200°C

-65 to +175°C

-65 to +175°C

-65 to +175°C

-65 to +175°C

-65 to +200°C

-65 to +175°C

-65 to +175°C

-65 to +175°C

-65 to +200°C

-65 to +175°C

-65 to +175°C

-65 to +175°C

-65 to +175°C

-65 to +200°C

-65 to +175°C

-65 to +200°C

-65 to +175°C

-65 to +175°C

-65 to +175°C

-65 to +175°C

-65 to +175°C

-65 to +175°C

-65 to +175°C

-65 to +175°C

-65 to +175°C

-65 to +175°C

-65 to +175°C

-65 to +200°C

-65 to +200°C

-65 to +175°C

-65 to +175°C

-65 to +200°C

-65 to +200°C

-65 to +175°C

-65 to +175°C

-65 to +175°C

-65 to +175°C

-65 to +175°C

-65 to +175°C

RoHS

Notes

Not recommended for new projects. LF is preferred.

Marine and geophysical applications.

Approved for MIL-DTL-38999L and MIL-DTL-83513G.

Not recommended for new projects. NF is preferred.

Glenair’s standard black anodize finish.

Glenair’s standard chem film finish.

Glenair’s preferred hardcoat finish.

Not recommended for new projects. JF is preferred.

Glenair’s preferred gold cadmium finish.

Glenair’s preferred clear cadmium finish.

Glenair’s standard electroless nickel finish.

Approved for MIL-DTL-38999L and MIL-DTL-83513G.

Not recommended for new projects. NF is preferred.

Glenair’s standard olive drab zinc-cobalt finish.

Glenair’s standard olive drab cadmium finish.

Use ZM for electroless nickel alternative.

Not recommended for new projects. LF is preferred.

Glenair’s preferred finish for titanium connectors.

Not recommended for new projects. UF is preferred.

Glenair’s standard black zinc-cobalt finish.

RoHS version of UC.

Glenair’s preferred black cadmium finish.

Approved for MIL-DTL-38999L.

Glenair’s standard unplated composite.

Glenair’s standard electroless nickel finish over composite.

Approved for MIL-DTL-38999L.

Not recommended for new projects. Use XB.

Glenair’s standard olive drab cadmium finish over composite.

Glenair’s standard black zinc-nickel finish over composite.

Glenair’s standard passivated stainless steel.

Glenair’s standard gold plating for space programs.

Glenair’s standard zinc-cobalt over stainless steel.

RoHS version of ZC.

Used on hermetic connectors. Use ZM for other applications.

Glenair’s preferred nickel-plated stainless steel.

Glenair’s new 1000 Hour Grey over stainless steel.

Glenair’s standard olive drab zinc-nickel finish.

Glenair’s standard black zinc-nickel finish.

Glenair’s RoHs compliant black zinc-nickel.

Glenair’s standard black cadmium over stainless steel.

Glenair’s standard olive drab cadmium over stainless steel.

1000

1000

1000

1000

500

1000

2000