C0402C758C5GAC7867

| Model | C0402C758C5GAC7867 |

| Description | Ceramic Capacitor, Multilayer, Ceramic, 50V, 33.3333% +Tol, 33.3333% -Tol, C0G, -/+30ppm/Cel TC, 0.00000075uF, 0402 |

| PDF file | Total 19 pages (File size: 1011K) |

| Chip Manufacturer | KEMET |

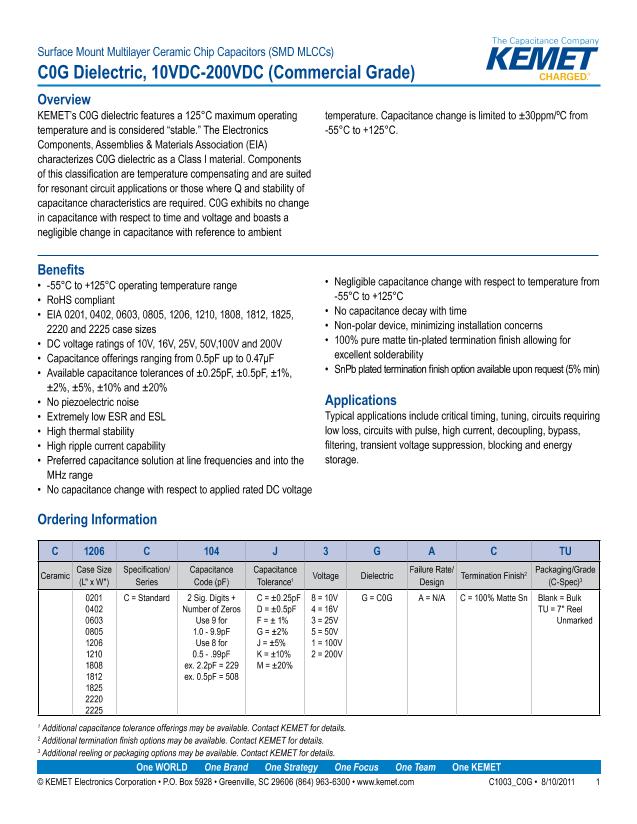

Surface Mount Multilayer Ceramic Chip Capacitors (SMD MLCCs) – C0G Dielectric, 10VDC-200VDC (Commercial Grade)

Table 2 – Chip Thickness/Packaging Quantities con’t

Thickness

Code

HG

JB

JC

JD

JE

JF

JP

JG

JH

JO

JP

JR

KB

KC

KD

KE

KF

Chip

Size

1825

2220

2220

2220

2220

2220

2220

2220

2220

2220

2220

2220

2225

2225

2225

2225

2225

Thickness ±

Range (mm)

1.60 ± 0.20

1.00 ± 0.15

1.10 ± 0.15

1.30 ± 0.15

1.40 ± 0.15

1.50 ± 0.15

1.60 ± 0.20

1.70 ± 0.15

1.80 ± 0.15

2.40 ± 0.15

3.50 ± 0.30

5.00 ± 0.50

1.00 ± 0.15

1.10 ± 0.15

1.30 ± 0.15

1.40 ± 0.15

1.60 ± 0.20

QTY per Reel QTY per Reel QTY per Reel QTY per Reel

7" Plastic

13" Plastic

7" Paper

13" Paper

1000

1000

1000

1000

1000

1000

1000

1000

1000

500

250

150

1000

1000

1000

1000

1000

4000

4000

4000

4000

4000

4000

4000

4000

4000

2000

850

600

4000

4000

4000

4000

4000

QTY per Bulk

Cassette

Thickness

Code

Chip

Size

Thickness ±

Range (mm)

QTY per Reel

7" Plastic

QTY per Reel

13" Plastic

QTY per Reel

7" Paper

QTY per Reel

13" Paper

QTY per Bulk

Cassette

Table 3 – Chip Capacitor Land Pattern Design Recommendations per IPC-7351

EIA

Size

Code

01005

0201

0402

0603

0805

1206

1210

1808

1812

1825

2220

2225

Metric

Size

Code

0402

0603

1005

1608

2012

3216

3225

4520

4532

4564

5650

5664

Density Level A:

Maximum (Most)

Land Protrusion (mm)

C

0.33

0.38

0.50

0.90

1.00

1.60

1.60

2.30

2.15

2.15

2.75

2.70

Y

0.46

0.56

0.72

1.15

1.35

1.35

1.35

1.75

1.60

1.60

1.70

1.70

X

0.43

0.52

0.72

1.10

1.55

1.90

2.80

2.30

3.60

6.90

5.50

6.90

V1

1.60

1.80

2.20

4.00

4.40

5.60

5.65

7.40

6.90

6.90

8.20

8.10

V2

0.90

1.00

1.20

2.10

2.60

2.90

3.80

3.30

4.60

7.90

6.50

7.90

C

0.28

0.33

0.45

0.80

0.90

1.50

1.50

2.20

2.05

2.05

2.65

2.60

Density Level B:

Median (Nominal)

Land Protrusion (mm)

Y

0.36

0.46

0.62

0.95

1.15

1.15

1.15

1.55

1.40

1.40

1.50

1.50

X

0.33

0.42

0.62

1.00

1.45

1.80

2.70

2.20

3.50

6.80

5.40

6.80

V1

1.30

1.50

1.90

3.10

3.50

4.70

4.70

6.50

6.00

6.00

7.30

7.20

V2

0.70

0.80

1.00

1.50

2.00

2.30

3.20

2.70

4.00

7.30

5.90

7.30

C

0.23

0.28

0.40

0.60

0.75

1.40

1.40

2.10

1.95

1.95

2.55

2.50

Density Level C:

Minimum (Least)

Land Protrusion (mm)

Y

0.26

0.36

0.52

0.75

0.95

0.95

0.95

1.35

1.20

1.20

1.30

1.30

X

0.23

0.32

0.52

0.90

1.35

1.70

2.60

2.10

3.40

6.70

5.30

6.70

V1

1.00

1.20

1.60

2.40

2.80

4.00

4.00

5.80

5.30

5.30

6.60

6.50

V2

0.50

0.60

0.80

1.20

1.70

2.00

2.90

2.40

3.70

7.00

5.60

7.00

Density Level A:

For low-density Product applications. Recommended for wave solder applications and provides a wider process window for reflow solder

processes. KEMET only recommends wave soldering of EIA 0603, 0805 and 1206 case sizes.

Density Level B:

For products with a moderate level of component density. Provides a robust solder attachment condition for reflow solder processes.

Density Level C:

For high component density product applications. Before adapting the minimum land pattern variations the user should perform qualification

testing based on the conditions outlined in IPC standard 7351 (IPC-7351).

© KEMET Electronics Corporation • P.O. Box 5928 • Greenville, SC 29606 (864) 963-6300 • www.kemet.com

C1003_C0G • 8/10/2011

8