PT0512-4S-025

| Model | PT0512-4S-025 |

| Description | MIL Series Connector, |

| PDF file | Total 24 pages (File size: 5M) |

| Chip Manufacturer | AMPHENOL |

26482 - AMPHENOL PT/PT-SE MIL-DTL-26482 SERIES I

146

C O N N E C TO R T O O LS

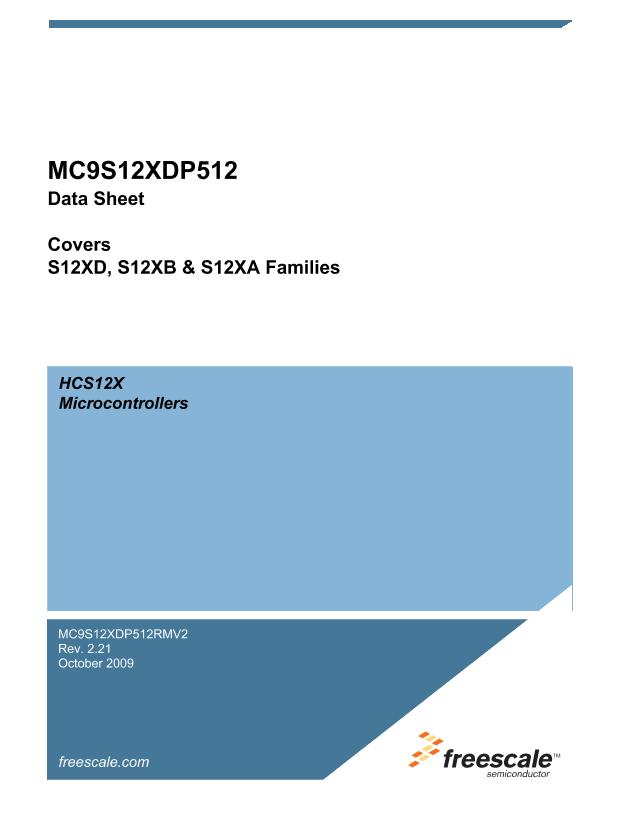

TG70 STRAP WRENCH

The strap wrench is used to

connect or disconnect

coupling nuts in a confined

space, or to tighten or loosen

endbells without damaging

the connector plating. A strap

wrench also increases torque,

allowing you to more easily

mate or unmate a connector

pair. Substitute tools, such as a pipe wrench or pliers, should

never be used because of the high probability of severe damage

to the connector plating or the coupling mechanism.

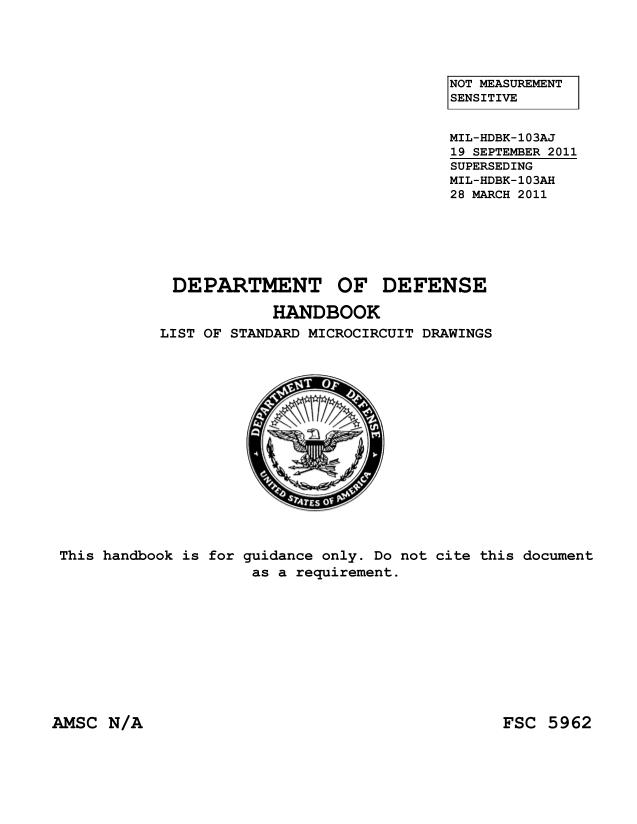

TG69P NON-MARRING ADJUSTABLE

ENDBELL PLIERS FOR FIELD SERVICE

The TG69P pliers

have resilient jaws

and are used to

tighten or remove

endbells without

damaging the

connector plating. The pliers are adjustable and will accommodate

all of the connector sizes in this catalog. Substitute tools, such as

a pipe wrench or metal jaw pliers, should never be used due to

the high probability of severe damage to the connector plating.

Replacement jaws, part number G77015, are available.

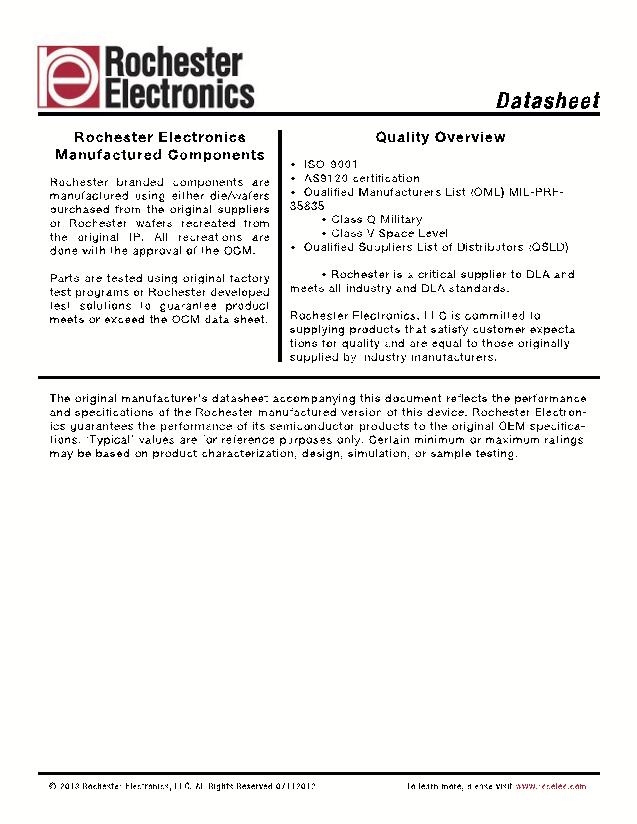

The 600 series is a complete system for the proper assembly and torquing of connector endbells. The system includes a bench-

mounted or hand-held torque wrench, plug and receptacle holders, and a range of endbell-tightening tools. When used together,

these tools provide consistent endbell installations. Each item is shipped with detailed assembly instructions.

PLUG & RECEPTACLE HOLDERS

SHELL

SIZE

ROTATIONS

PIN

W=G

X=I

8

10

12

14

16

18

20

22

24

MIL-DTL-26482

FOR PT, PT-SE, MS311_, MS312_

RECEPTACLES

600D005-8R

600D005-10R

600D005-12R

600D005-14R

600D005-16R

600D005-18R

600D005-20R

600D005-22R

600D005-24R

PLUGS

600D005-8P

600D005-10P

600D005-12P

600D005-14P

600D005-16P

600D005-18P

600D005-20P

600D005-22P

600D005-24P

SOCKET

W=H

X=J

Y=L

Z=N

600-007

Bench-mounted

torque wrench

600-004

Y=K

Z=M

Hand-held

torque wrench

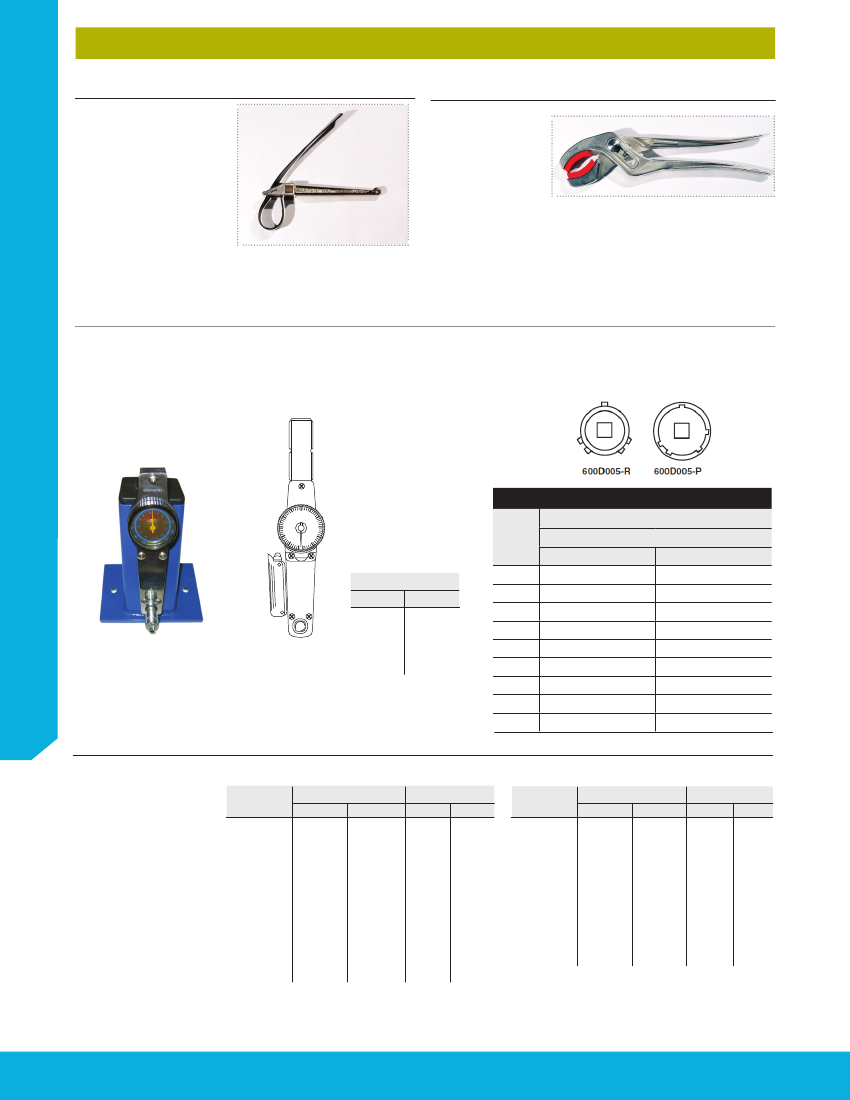

TORQUE VALUES

IMPORTANT NOTE:

If barrel/shell has three

threads or less, torque to

30 to 35 inch/Lbs (3.4 to

4.0 NM) per L-725-2.

Endbell

SHELL

SIZE

6

8

10

12

14

16

18

20

22

24

Jam Nut

INCH-LBS.

MIN

MAX

20

20

26

30

40

50

60

75

85

100

26

26

32

36

46

55

65

80

90

110

MIN

2.3

2.3

2.9

3.4

4.5

5.6

6.8

8.5

9.6

11.3

N-M

MAX

2.9

2.9

3.6

4.1

5.2

6.2

7.3

9.0

10.2

12.4

SHELL

SIZE

8

10

12

14

16

18

20

22

24

INCH-LBS.

MIN

MAX

26

30

46

55

70

80

90

100

110

32

36

50

60

75

85

95

110

120

MIN

2.9

3.4

5.2

6.2

7.9

9.0

10.2

11.3

12.4

N-M

MAX

3.6

4.1

5.6

6.8

8.5

9.6

10.7

12.4

13.6

For assistance in North America: +1 800.675.1214 • www.peigenesis.com • sales@peigenesis.com